-40%

1966 Bridgestone 175 Dual Twin Motorcycle Road Test - 3-Page Vintage Article

$ 7.6

- Description

- Size Guide

Description

1966 Bridgestone 175 Dual Twin Motorcycle Road Test - 3-Page Vintage ArticleOriginal, Vintage Magazine article.

Page Size: Approx. 8" x 11" (21 cm x 28 cm) each page

Condition: Good

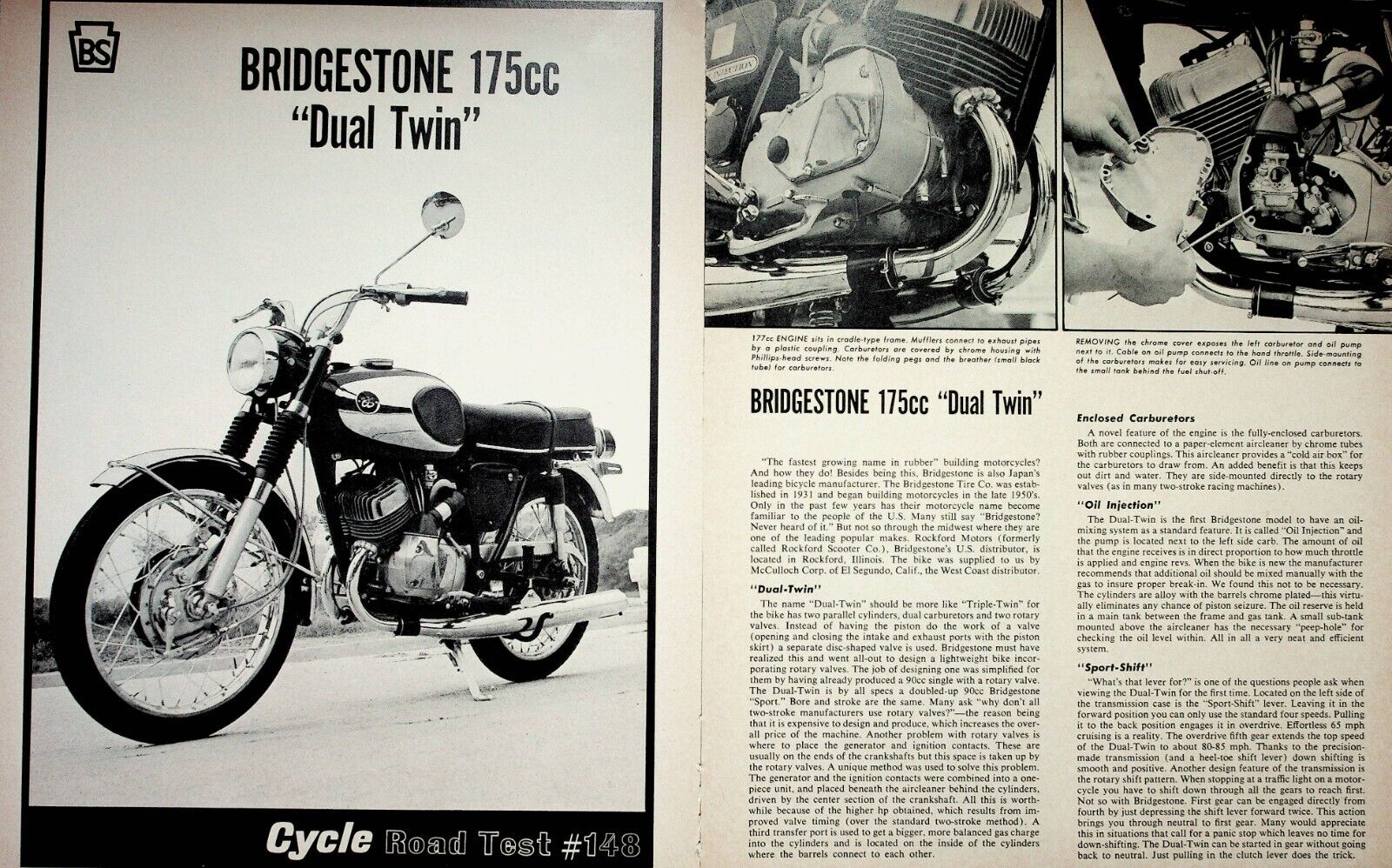

® BRIDGESTONE 175cc

“Dual Twin"

177cc ENGINE sits in cradle-type frame. Mufflers connect to exhaust pipes

by a plastic coupling. Carburetors are covered by chrome housing with

Phillips-head screws. Note the folding pegs and the breather (small black

tube) for carburetors.

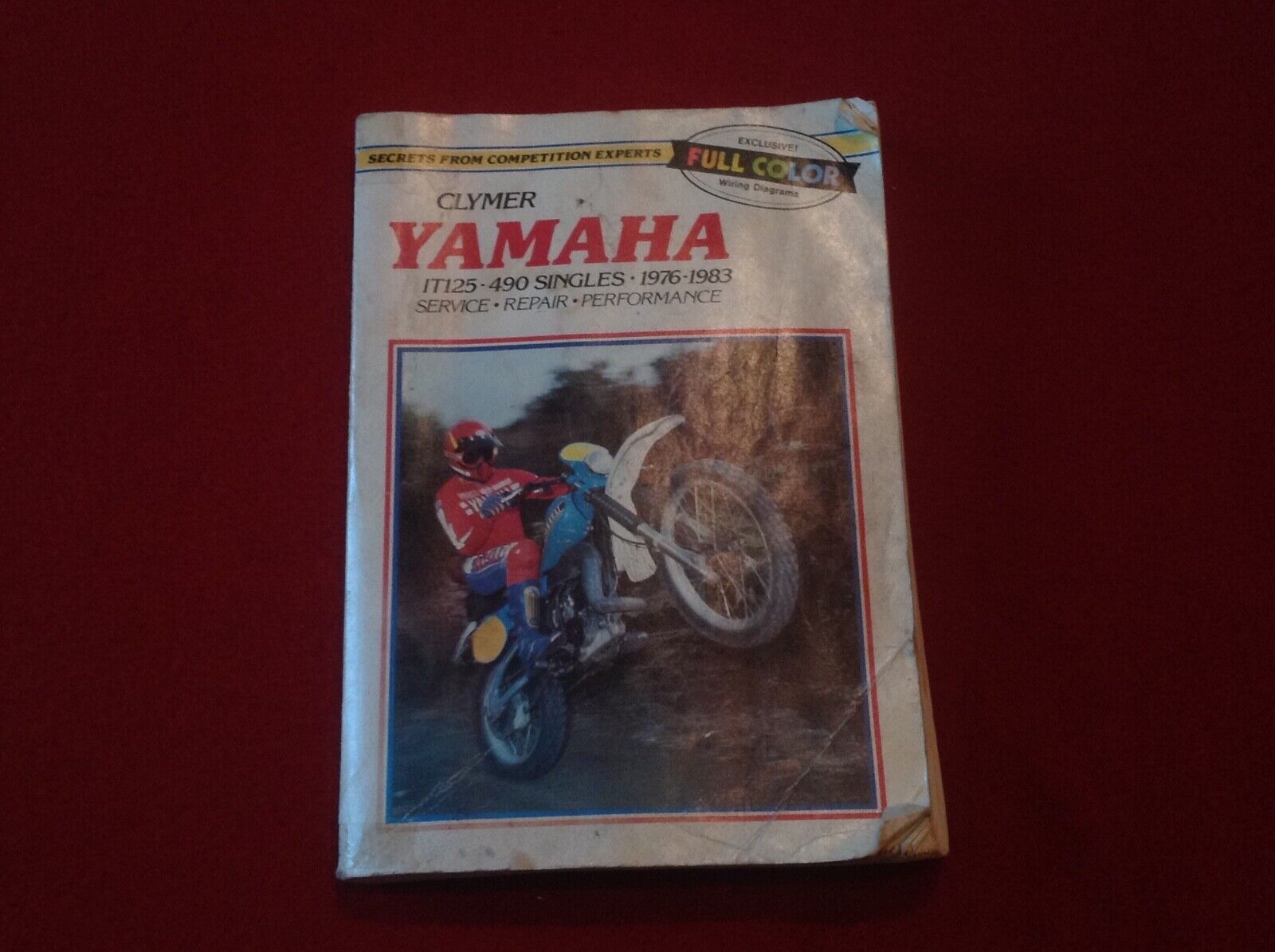

REMOVING the chrome cover exposes the left carburetor and oil pump

next to it. Cable on oil pump connects to the hand throttle. Side-mounting

of the carburetors makes for easy servicing. Oil line on pump connects to

the small tank behind the fuel shut-off.

BRIDGESTONE 175cc “Dual Twin”

Cycle [S©si(fl

“The fastest growing name in rubber” building motorcycles?

And how they do! Besides being this, Bridgestone is also Japan’s

leading bicycle manufacturer. The Bridgestone Tire Co. was estab-

lished in 1931 and began building motorcycles in the late 1950’s.

Only in the past few years has their motorcycle name become

familiar to the people of the U.S. Many still say “Bridgestone?

Never heard of it.” But not so through the midwest where they are

one of the leading popular makes. Rockford Motors (formerly

called Rockford Scooter Co.), Bridgestone’s U.S. distributor, is

located in Rockford, Illinois. The bike was supplied to us by

McCulloch Corp, of El Segundo, Calif., the West Coast distributor.

“Dual-Twin”

The name “Dual-Twin” should be more like “Triple-Twin” for

the bike has two parallel cylinders, dual carburetors and two rotary

valves. Instead of having the piston do the work of a valve

(opening and closing the intake and exhaust ports with the piston

skirt) a separate disc-shaped valve is used. Bridgestone must have

realized this and went all-out to design a lightweight bike incor-

porating rotary valves. The job of designing one was simplified for

them by having already produced a 90cc single with a rotary valve.

The Dual-Twin is by all specs a doubled-up 90cc Bridgestone

“Sport.” Bore and stroke are the same. Many ask “why don’t all

two-stroke manufacturers use rotary valves?”—the reason being

that it is expensive to design and produce, which increases the over-

all price of the machine. Another problem with rotary valves is

where to place the generator and ignition contacts. These are

usually on the ends of the crankshafts but this space is taken up by

the rotary valves. A unique method was used to solve this problem.

The generator and the ignition contacts were combined into a one-

piece unit, and placed beneath the aircleaner behind the cylinders,

driven by the center section of the crankshaft. All this is worth-

while because of the higher hp obtained, which results from im-

proved valve timing (over the standard two-stroke method). A

third transfer port is used to get a bigger, more balanced gas charge

into the cylinders and is located on the inside of the cylinders

where the barrels connect to each other.

Enclosed Carburetors

A novel feature of the engine is the fully-enclosed carburetors.

Both are connected to a paper-element aircleaner by chrome tubes

with rubber couplings. This aircleaner provides a “cold air box” for

the carburetors to draw from. An added benefit is that this keeps

out dirt and water. They are side-mounted directly to the rotary

valves (as in many two-stroke racing machines).

“Oil Injection”

The Dual-Twin is the first Bridgestone model to have an oil-

mixing system as a standard feature. It is called “Oil Injection” and

the pump is located next to the left side carb. The amount of oil

that the engine receives is in direct proportion to how much throttle

is applied and engine revs. When the bike is new the manufacturer

recommends that additional oil should be mixed manually with the

gas to insure proper break-in. We found this not to be necessary.

The cylinders are alloy with the barrels chrome plated—this virtu-

ally eliminates any chance of piston seizure. The oil reserve is held

in a main tank between the frame and gas tank. A small sub-tank

mounted above the aircleaner has the necessary “peep-hole” for

checking the oil level within. All in all a very neat and efficient

system.

“Sport-Shift”

“What’s that lever for?” is one of the questions people ask when

viewing the Dual-Twin for the first time. Located on the left side of

the transmission case is the “Sport-Shift” lever. Leaving it in the

forward position you can only use the standard four speeds. Pulling

it to the back position engages it in overdrive. Effortless 65 mph

cruising is a reality. The overdrive fifth gear extends the top speed

of the Dual-Twin to about 80-85 mph. Thanks to the precision-

made transmission (and a heel-toe shift lever) down shifting is

smooth and positive. Another design feature of the transmission is

the rotary shift pattern. When stopping at a traffic light on a motor-

cycle you have to shift down through all the gears to reach first.

Not so with Bridgestone. First gear can be engaged directly'from

fourth by just depressing the shift lever forward twice. This action

brings you through neutral to first gear. Many would appreciate

this in situations that call for a panic stop which leaves no time for

down-shifting. The Dual-Twin can be started in gear without going

back to neutral. Just pulling in the clutch lever does the trick...

16515